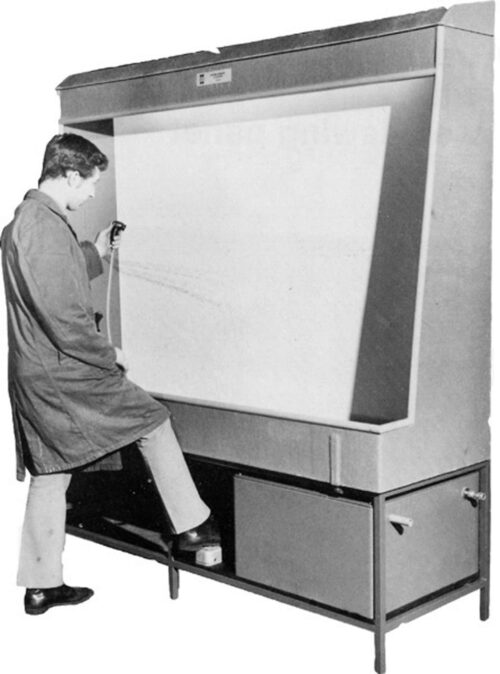

- The T162SS silk screen exposure unit has been developed from the very successful and well-proven T162 Rotex plate printing down unit used in the graphic art’s trade over many year’s.

- It consists of a robust metal cabinet that splits into two for ease of installation where access is limited. The lower section contains the light source, power pack and suction pump, whilst the upper cabinet has the control box fitted onto the front face with the glass and blanket frame mounted on the top.

T162SS Silk Screen Exposure Unit

Description

The blanket frame is pivoted at the rear and is held open by gas dampers. Air is drawn out through a series of holes around the inner face of the frame so allowing the flexible rubber sheet to be pulled down over the screen frame quickly and efficiently.

There are 3 versions available, for each of the 2 sizes of machine. The basic unit is fitted with a timer with which to control the exposure, and no shutter, so the lamp will strike to carry out the exposure, and then shut off, this unit is adequate where a small number of screens per day are required, less than 30.

For more accurate control of the exposures, an integrator model is available, but still using the same lamp unit, with no shutter, so for lower production environments, but with more accurate control of exposure.

For higher production environments, where a larger number of screens are produced, or one exposure, following immediately after the other is required, then a shuttered light source is used, along with an integrator to control the exposure time

- Integrator models have 8 user-selectable memories.

- All the machines use a 2kW light source.

- A 4kW version is available for slower resists.

- Larger machines are available on request.

These units are very well suited to schools, colleges and studios, who require a simple to operate, robust, reliable and fast exposure unit.